Particle Probes

The preferably regular use of particle probes is suitable for monitoring fuel changes and process adjustments. These probes support the plant operator in recognising leeway in the boiler design and in adjusting the mode of operation and the fuel in such a way that corrosion and fouling are reduced.

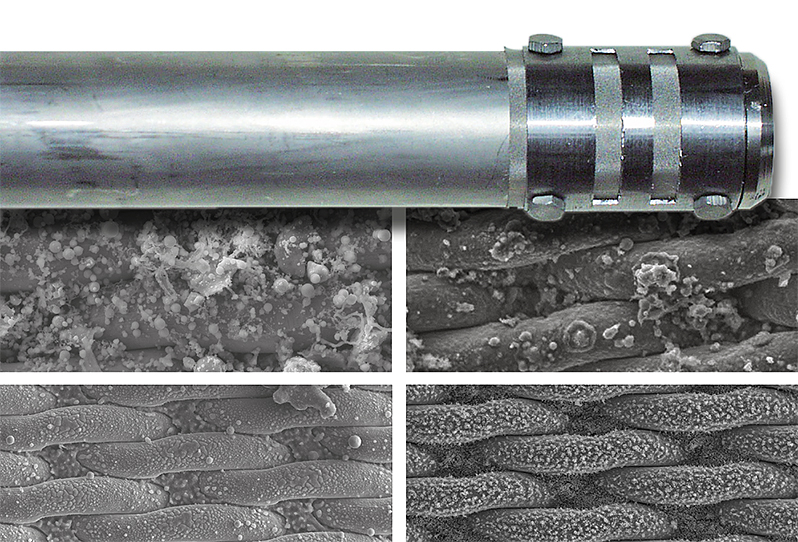

For this, the grid probe is inserted into the flue gas flow for a few seconds. The flue gas is sucked through a micrometre-fine grid and the salts and ashes are deposited on the surface. We analyse these deposits and can use them to provide information on corrosion and fouling tendencies.

Further information on the grid probe can be found in our flyer.

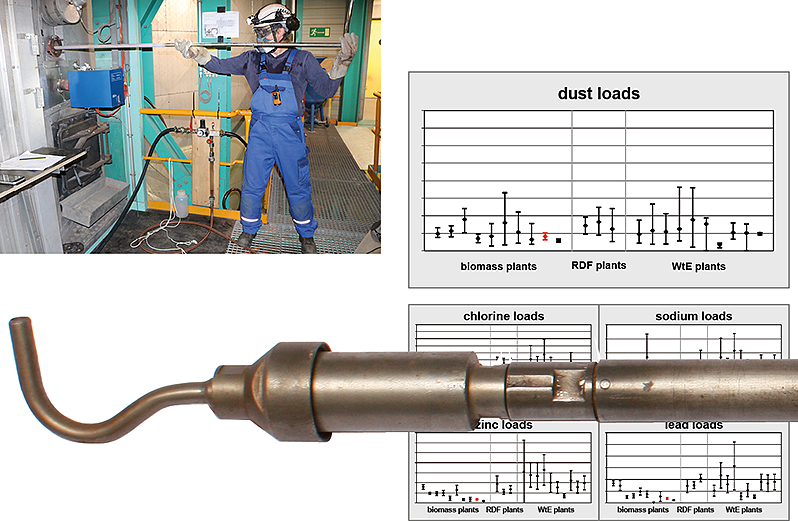

We insert a sampling probe into the flue gas at the end of the boiler for about 30 to 60 minutes to determine the ash-salt proportion (ASP). The analysis of the flue gas particles with regard to their chemical composition provides information on the total dust load and the load of individual elements, which can then be used to optimise operation with regard to corrosion and fouling.

Further information on the ASP can be found in our flyer.